Wa Tech => Tanker Waste Facilities - Wa Tech WLL => Electromechanical Works O&M

Plants / Facilities

Tanker Waste Plant | |

=> | In Concrete and Container Design |

=> | System are Modular |

=> | System is easily Transportable at all the Time |

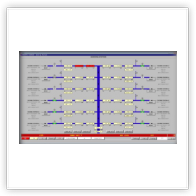

=> | Variety of Tanker Docking Stations in a closed Design |

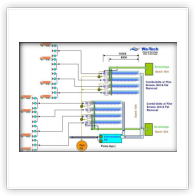

=> | Measuring Stations at the Docking Stations or in the Iintermediate Pumping Station |

=> | Measuring Stations such as Flow Measurement, pH Value, Conductivity, COD Concentration |

=> | With Rake, Sand and Fat Trap, Screenings Treatment |

=> | Additional Biological or UF Cleaning System |

=> | SCADA and PLC |

=> | An autonomous system can be realized |

=> | Air cleaning system (Odor) |

=> | Laboratory |

=> | and according to your wishes |

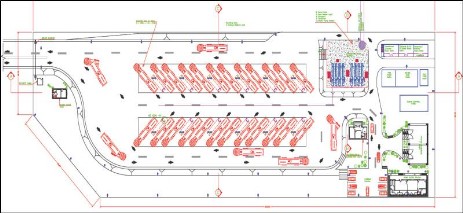

Introduction Tanker Waste Facilities (as an example)

When tankers arrive at the Tanker Waste Plant, they are allocated a slot by the operator. Should all docking stations be occupied during the time of arrival, the system will calculate the next available slot by estimating the remaining time for each tanker to discharge completely. This is possible because the size of each tanker is registered within the system and the volume discharged at any given time is recorded by the EFM at each docking station.

Note that currently tanker drivers bring a shipping list that is supposed to be collected and the data entered into a recording system at the Tanker Waste Facilities. Currently the registration number of the truck (license plate), tanker capacity, driver info, collection date, property owner name of septage to be discharged and property address. This data will be entered by the operator into the database of the system at the Tanker Waste Plant.

After arriving at the discharge point the truck driver connects the discharge hose to the Perot coupling at his truck and at the docking station. This creates a closed coupling between truck and docking station so that no water should spill during tanker discharging. To start the discharging procedure the tank driver now must push the green START button at the control box located in the middle of the twin docking station.

Upon starting of the discharge system, the SCADA opens the gate valve and discharging begins. After discharging is complete the truck driver can push the red STOP button to close the gate valve at the docking station. The EFM records the discharged flow once the drivers has initiated the system. After a zero flow is recorded the gate valve closes automatically.

Signals are recorded directly at the docking station, but signal transmitters will be placed in the pressurised existing tankered waste control room of the Tanker Waste Plant in order to protect them from the harsh environment at the docking stations.