Wa Tech => Sewage Facilities, MBR - Wa Tech WLL => Electromechanical Works O&M

Plants / Facilities

Membran Facilities | ||

=> | Reduction of Activated Sludge Basin Volume | |

=> | Very Space Saving Building Method | |

=> | Secondary Settler, Filter, Desinfection not applicable | |

=> | High chem. Effluent Quality | |

- | Water can be reused for irrigation | |

=> | Solid & Germ free Effluent | |

- | Desinfection | |

- | Water Recycling | |

Process Description of an

Ultra Filtration Facility of

Wa Tech Water Technology WLL

The wastewater passes into bioreactor where biological purification of the sewage water by activated sludge, a mixture of a number of micro-organisms, occurs.

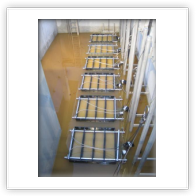

The process is an aerobic one where the oxygen for respiration of the activated sludge must be delivered into the tank. The blowers continuously deliver air into the system which is then distributed into the bioreactor via the aeration elements. This air, whilst serving to keep the filtration modules clean, also ensures delivery of the required amount of oxygen to the micro-organisms within the process. Simultaneously the volume of the bioreactor is mixed to ensure the contact of sewage water with the activated sludge.

The first stage is continuously re-circulated to the membrane compartment by means of the recirculation pump. This membrane compartment maintains a constant level by overflowing back into the first stage compartment.

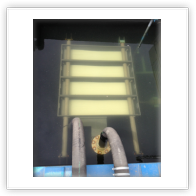

This feature allows for much greater flexibility during maintenance where it is no longer necessary to discharge the entire contents of the tank for internal access. The purified water is separated from the activation sludge by means of filtration modules. The filtration modules create safe, physical, barriers for the activation sludge, bacteria and some viruses. As a result, the filtered water does not need to be further disinfected.

The purified water is removed under a small vacuum created on the clean side of the filtration elements by the progressive cavity filtrate/permeate discharge pump with frequency converter.

The filtration modules are continuously cleaned to prevent fouling by the activated sludge. This is achieved by locating the aeration elements uniformly under the filtration modules. An integrated cleaning chamber is included in the main stainless steel tank for periodic membrane cleaning.