Wa Tech => Sewage Water Lifting System - Wa Tech WLL => Electromechanical Works O&M

Single Equipment

Fluid Lifting Station | |||

=> | For Temporary Use or Permanent Installation | => | Autonom working system with generator |

=> | Archemedial Screw Pump | => | Centrifugal Pump |

=> | Self-Supporting Steel Trough | => | Direct Drive with Soft Start |

=> | Concrete Trough | => | Easy and Quick Mounting |

=> | Direct Drive with Soft Start | => | Compact Lifting Station |

=> | Transmission with V-Belt Drive | => | Easy Change |

=> | Gentle Sludge Lifting | => | Fast-Circuit Coupling |

Containerized

According to the conditions on-site one or the other type of pump may be better suited.

If space is very tight and you have to overcome great heights, centrifugal pumps are better suited.

If the water for lifting is particularly loaded with sand and stones, the Archimedean screw pump is better.

The auger pump can also be used as an energy pump. Through the running water we put the screw in rotation and drives a generator.

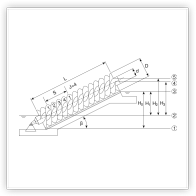

The principle of the Archimedean Water Screw Conveyor is a pipe placed at an angle, equipped with a blading which, by means of rotational movements, transports different arts of liquid to a higher level.

The Archimedean water screw conveyor has the advantage that the machine can not be clogged by the open design and the impurities can be processed without difficulty without the efficiency is adversely affected. Because the screw works without clogging, a possible computer system behind the screw can be planned, resulting in lower construction costs.

Furthermore, the efficiency of screws is much cheaper than with other types of pumps, e.g. Centrifugal pumps.

Archimedean screw conveyors are much better suited to changing, fluctuating inlets because the efficiency remains approximately constant. This is further supported by the low speeds of the screws.

The construction of the Archimedean water screw conveyor from an electric motor, gearbox, upper and lower bearing restricts maintenance to an annual oil change and regular checking of the lubrication points.

These factors together result in very low operating costs for our screw systems.

Pipe worms have the particular advantage that the outer screw tube is the water guide and is formed at both ends as a bearing carrier. The outlet box, welded to the upper end of the pipe and equipped with a support bracket, serves for the upper, pivotable worm pump bearing. The lower end of the pipe is suspended by an angle lever by means of an adjustable suspension lug on a crossbar. Furthermore, a special, watertight, maintenance-free worm foot bearing with oil back pressure lubrication is integrated in the lower end of the pipe.

Trough Execution

When choosing the troughs you have different options:

- Concrete Trough, whereby the auger is used to "turn in" the trough. For this one uses a special mortar at a very low speed. Optionally, one can use a screw including Stahlstürzschablone, which is taken away after casting the concrete, thus giving a true gap between the screw and trough.

- Steel Trough, which can remain in the concrete after casting.

- Self-Supporting Steel Trough, with built-in screw, which is completely prefabricated in the factory Consisting of: trough, bearing and drive. The advantage of this variant is the shorter assembly time.

- Pipe Steel Trough, with upper and lower, integrated worm bearing which are connected to the outer tube and serve as a bearing carrier. Due to the self-supporting construction and suspension in traverses a casting or a firm connection of the pipe screw with the concrete structure is not necessary. This results in the shortest assembly time and the simplest installation of all types of hydraulic lift screw.